GigaTrak RFID Tool Inventory Tracking System

Track your tools & equipment anywhere with GigaTrak RFID Barcode Tracking System

GigaTrak’s RFID Tool Tracking Systems allow you to track your company’s equipment anytime and anyplace. To make things better, GigaTrak software doesn’t limit number of items that can be tracked!

Our RFID asset management software can help your company accurately and efficiently track any of your business’ assets. Stop wasting time searching for and replacing lost assets. You can now keep track of all your valuable assets with a convenient, easy to use, complete RFID asset tracking system.

GigaTrak helps organizations improve the visibility of their fixed assets by enabling them to automate physical asset inventories. Track the movement of assets and monitor items in real-time for security and safekeeping. Different technologies like RFID, barcodes, and others can be used to track utilization of assets, depending on customer needs.

RFID label tracking makes it easy to track and manage tools and inventory. This is applicable both in the warehouse and out on the job. GigaTrak provides a powerful tool and equipment management system. It allows contractors, construction, maintenance and repair organizations to gain control of their tool and equipment inventory.

Why Should I Use GigaTrak’s Asset Management Systems?

Drastically improve accountability using GigaTrak’s tool inventory control software. A barcode labeling inventory system helps you keep accurate inventory records. It can be used to track tools, office equipment, intangible assets, documents, rental equipment, and other items that are often passed around.

Stock visibility is key! An effective RFID tool tracking software makes it easy to know where your tooling and equipment is or who it is assigned to. Track a tool for its whole lifecycle. From the date of purchase, when that item has been checked out to a project/person, moved to another location/person, and checked back into their proper storage area in real time.

RFID (radio frequency identifier) tags are small tags that can be read by wireless, non-contact readers. They are used to track and manage assets (such as computer equipment, printed documents or vehicles).

RFID tags have several advantages over barcodes:

- An RFID tag can be read from a near by reader, so you don’t have to position the item as exactly as when reading a bar code.

- Longer read ranges with RFID Technology compared to barcodes dependent on size of RFID tag and RFID handheld scanner.

- RFID tags can be read when they are covered or not in the line of sight – a tag can be read even if it is inside a box, carton or case.

- Read multiple RFID tags at once – unlike bar codes, which can only be read one at a time.

What Is an Asset or Tool?

The RFID tag system helps you stay organized and efficiently track tool records. Check the accuracy of physical inventory counts, set up suitable storage areas, and keep track of losses, damages and breakages.

A good solution is using RFID labels and RFID enabled software tracking of all tools, large or small. An RFID tracking system can save a company money by tracking tools to employees, jobsites, or specific locations.

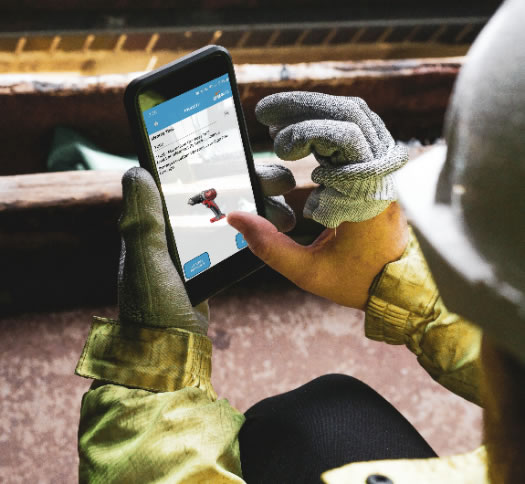

Software, labels, barcode scanners, RFID readers and cell phones are used to execute transactions quickly and securely. Track items, restrict loss, oversee maintenance, manage supply costs through accurate records and track trends. With a single inventory system, all these tasks can be managed efficiently and effectively.

Assets tracked include but aren’t limited to:

- Computer Equipment

- Individual Tools

- Printed Documents

- Vehicles

- Inventory

- Supply Chain Equipment

- Consumables

- Product Samples

- Rental Items