Barcode Tracking Software

GigaTrak Equipment Tracking Software Expected to Reduce Losses and Save Tracking Time

GigaTrak’s barcode tracking systems make it easier to track and manage your assets, tools and inventory in the warehouse and out on a project. Improve inventory visibility with our barcode inventory system. The Tool Tracking System reduces your losses and saves tracking time for contractors, utilities and other maintenance groups with valuable tools and equipment that need to be managed.

GigaTrak provides a powerful barcode tool tracking solutions that allows businesses, schools, contractors, construction, maintenance, and repair organizations to gain control of their tools and equipment inventory. Our software is easy to implement and use. It uses a simple barcoding system to track assets, tools, inventory, and equipment. Tracking equipment with a barcode provides a quick, easy way to document and track equipment.

GigaTrak’s Tool Tracking Software is available in three versions – Tool Tracking Basic, Pro, and Contractor Editions designed with the user in mind. Please contact us today to see the differences between the editions. Our sales team will discuss your tracking needs to best suggest what system edition is best for your business.

Why Should I use Barcode Tracking Software Systems?

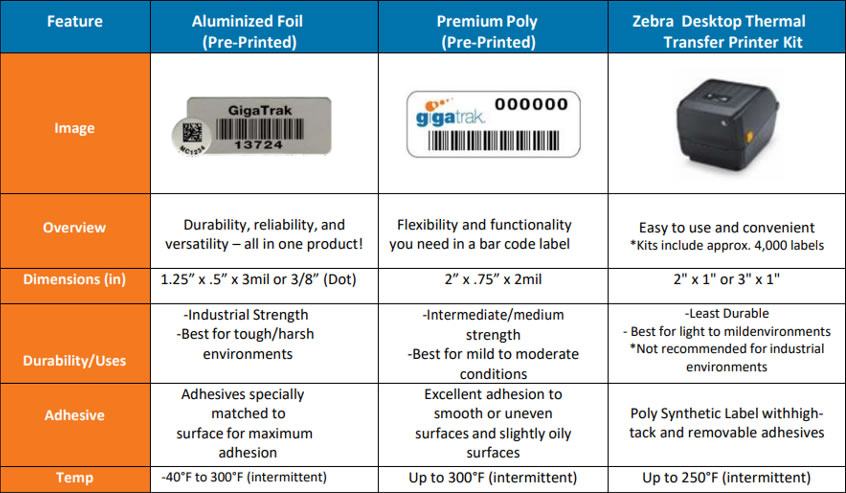

GigaTrak offers various barcode tracking software: Asset Tracking, Inventory Management and Tool Tracking software. By applying a barcode label on each item, you will save time and human error – typing or reading the number or letters. Barcode labels can be used in many applications and come in many different sizes. GigaTrak offers durable pre-printed barcode labels, or you can have them customized with your company’s name or logo.

Bar coding can be done using traditional 1D (1 dimensional ), 2D (2 dimensional) barcodes or RFID tags. RFID barcode label information can be provided per request.

What are Assets, Tools and Inventory?

Our software, labels, barcode scanners, and even cell phones can be used to execute transactions quickly and securely, monitor the location of items within the inventory, restrict loss through tracking and accountability, oversee maintenance of the inventory system for optimal performance, and manage supply costs by keeping accurate records and tracking trends in demand. With a single inventory system, all these tasks can be managed efficiently and effectively.

Types of inventories that can be tracked include but aren’t limited to:

- Individual Tools

- Bulk Inventory

- Machinery

- Fleet(s) and Vehicles

- Raw Materials

- Safety Stock

- Consumables

- Supply Chain Equipment

- IT/Corporate Assets

- Rental Tools/Equipment