RFID vs Barcode Tracking for Asset Management

The Pros and Cons of RFID vs Barcode

Understanding the differences between RFID and barcodes in asset management is important for companies with any size inventory. Our article breaks down both options, and helps you determine which tracking system is best for your business. Barcodes have been the go-to technology for tracking inventory for decades, but RFID is increasingly being adopted as a more sophisticated option.

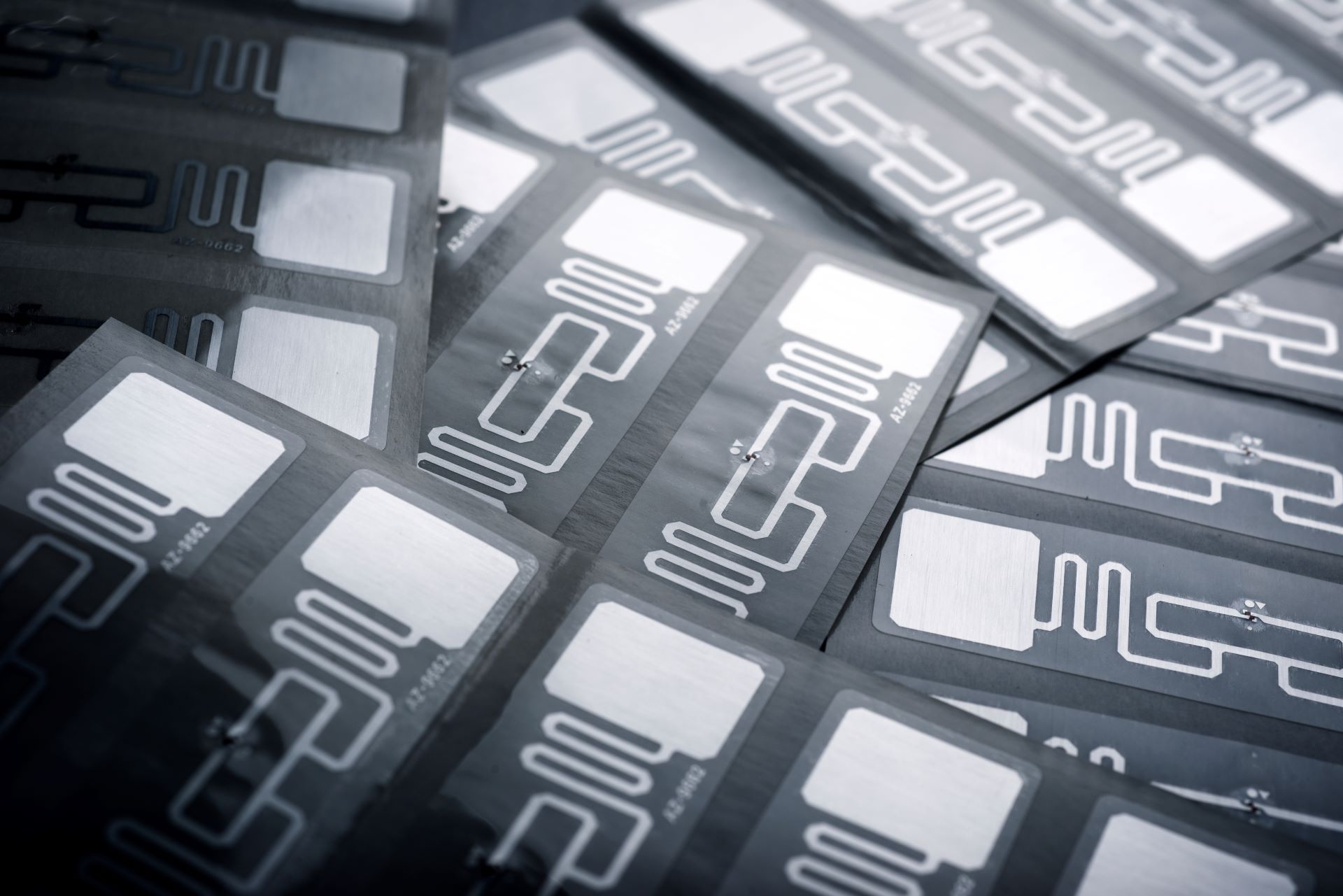

When it comes to tracking assets, there are two main options: RFID and traditional barcodes. Barcode solutions require a reader which can be a cell phone and the barcodes themselves. RFID requires tags in place of the barcodes a more expensive RFID reader or sled in place of the barcode reader. Both have their advantages, so it’s important to understand the difference between them before deciding what option would fit the best. So, what are the advantages of each?

ADVANTAGE RFID

- Can discover and audit multiple items at once

- Line of sight is not required

- RFID tags are resistant to damage and wear and tear

- Ideal for checking in multiple items at one time

- Geiger counter mode allows you to find assets that are hidden

ADVANTAGE BARCODES

- Barcodes and Scanners are relatively inexpensive compared to RFID options.

- Barcodes are much a much easier to technology to implement.

- You can start with just the camera in a cellphone.

- More tag choices and you can often print barcode labels yourself

- Barcodes have a higher degree of read accuracy

Both technologies have their niche in helping companies increase inventory accuracy and driving cost out of the process, but the decision isn’t always easy. Contact our sales team to learn which is the best option for your company. Call us at 833-444-2872 or email us sales@gigatrak.com.